We produce an ultra premium grade BBQ pellet, where less than 1% ash content is produced in a hardwood containing NO tree bark. We use only the heart of the wood. The wood is dried in our a tumble drier. Moisture content is extremely important to the flavor coming from a wood pellet. The higher the moisture is the more Phenols and Terpenes are present. This is the mostly unknown fact of ultra premium quality BBQ pellets.

Most processed hard woods are made into boards for cabinets and flooring. That material is dried in kilns to an extremely low moisture content. When this happens, much of the phenols are no longer present. This is why when you are looking at much of the social media of pellet grill users, their comment is all pellets to them taste the same. Also economics make a major roll in this too. Most sawmills who process hard wood for construction use need it removed from their sites. This material made into pellets and gets used as heat fuel. Also it’s exported for power plant operations in Europe where coal fired facilities must use a minimum of 5% carbon natural fuel.. Some makers are grinding whole trees. Usually those companies are talking about bark adds flavor to there product.

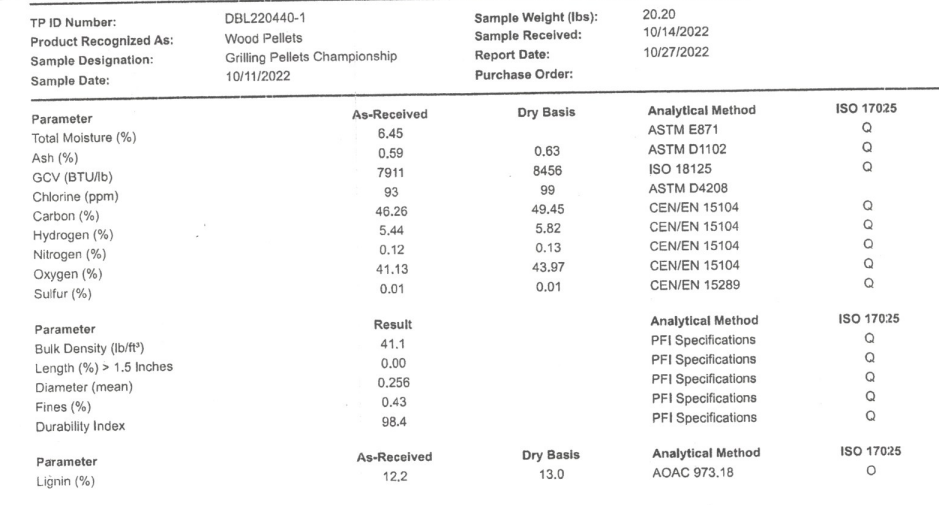

Fruit trees don’t grow very large in diameter and separating the smaller limbs become time and labor intensive. Plus more waste to dispose of. These products have a higher ash content and some produce a crusty clump in the fire pots called a clinker. Your cleaning out of your cooker needs to be very regular with this type of product. Also you will notice a lot more pellet usage and struggle for higher temperatures with these type of pellets. Posted below is the lab report for Championship pellets. if anyone ever posts their reports please pay close attention to Moisture is 6.45% and Ash at 0.59%.